BMT has designed many ‘special purpose’ and automated machines for customers with specific requirements.

These include the design and production of robotic wagon vibrators for releasing coal from bottom dump rail wagons to portable, numerically controlled grinders for removing high loads from dragline roller circles.

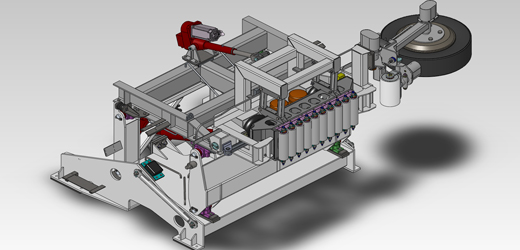

Robotic Wagon Vibrator

Many high-capacity coal export terminals, which receive coal by rail in bottom-dump wagons, experience major delays due to discharge failure when handling sticky coal. These delays can have a serious impact on the capacity of the rail system feeding the port and on the terminal inloading capacity. To address this problem, BMT has developed a fully automatic robotic wagon vibrator.

Vibrators are installed in a dump station, at fixed locations adjacent to the track. As the wagons roll past, the vibrator lands on and tracks the lower sill of each wagon, retracting automatically at the wagon end. Failure of the coal to discharge when the bottom dump doors are opened is detected automatically, activating the vibrator, which dislodges the coal.

Use of the robotic vibrator brings significant benefits to coal terminal inload operations by reducing unloading delays, increasing throughput, reducing manning levels, improving safety, as well as eliminating possible structural damage to the wagons themselves.

These services are provided by our specialist operating company in Australia.

For general enquiries relating to Special Purpose Machines, please contact Deryck Ethelston

Contact

Deryck Ethelston

Ports, Infrastructure and Resources Managing Director

Tel: (0)208 943 5544

Fax: (0)208 943 5347

Email

BMT Group

Download Business Card

Related Services

Related Companies

Related Projects

BMT Mining and Bulk Handling Brochure

An overview of BMT’s capabilities within the Mining and Bulk Handling sector.

Download

Follow Us